Extremely High Power Output and Measurement Accuracy

The system adopts a 20-bit resolution data acquisition module to measure the output voltage, current, and relative luminance of silicon photodiodes across all channels. Meanwhile, the software can correct the power output based on the voltage and current values measured by the system, ensuring the current output error is less than 2uA.

Measurement and Subtraction of Silicon Photoelectric Dark Current Noise

Even in the absence of any light, silicon photodiodes generate a weak current due to ambient temperature (heat), known as dark current noise. Dark current noise is not a fixed value; it increases with temperature. Fostar's silicon photoelectric lifetime testing machine measures and stores the dark current noise of each silicon photodiode before starting luminance measurement. Each measurement result of the silicon photoelectric current is automatically subtracted by the dark current noise, and luminance is calculated using the net silicon photoelectric current.

Extremely High Accuracy in Relative Luminance Measurement

Thanks to the system's high-precision measurement, elimination of silicon photoelectric dark noise, and the linearity of Hamamatsu silicon photodiodes exceeding 99.5%, the entire system achieves extremely high accuracy in relative luminance measurement. The silicon photodiodes typically used are Hamamatsu models S1223 (2.42.8 mm, ambient temperature) / S2386-44K (3.63.6 mm, high temperature: -40℃~100℃), with a measurement deviation from CS2000A of <0.3%.

Enriched Testing Requirements for Silicon Photoelectric Pulse Modes

All channels can perform pulse mode measurements, with configurable parameters such as bias voltage, amplitude, frequency, and duty cycle (optional function).

More Comprehensive Test Preprocessing Functions

In addition to temperature, the software can set preprocessing for 4 modes: voltage, current, pulse voltage, and pulse current. It also supports setting two preprocessing cycles, facilitating voltage and current preprocessing after temperature preprocessing. Preprocessing and lifetime test data can be saved separately.

Added Accompanying Mini-Program for Lifetime Data Viewing

Current data and previously tested data can be added to the data list to generate lifetime curves, making it convenient for customers to compare test results before and after.

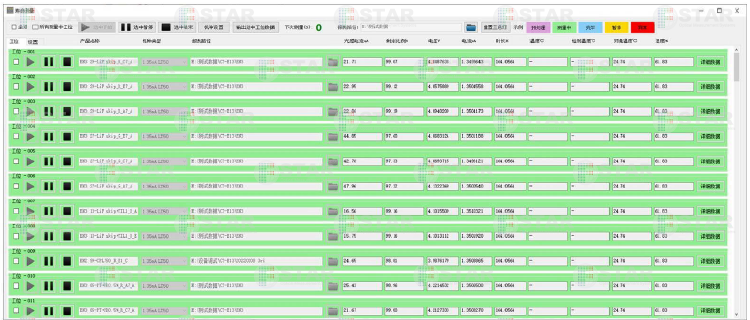

(1) Measurement Modes: Constant voltage, constant current, square wave voltage, square wave current

(2) All channels of the software can be independently configured with current and voltage test conditions without mutual interference.

(3) All channels of the software allow real-time checking of detailed measurement data and charts.

{{data.abstract || "No product introduction available"}}