Airborne Display and Lighting Optical Testing Systems

Aerospace displays must operate stably in extreme environments (such as high-altitude low pressure, strong radiation, and drastic temperature differences) to provide accurate information for pilots or astronauts. Their optical performance evaluation focuses on the following core aspects:

● Extreme Environment Adaptability: Within a wide temperature range of -55℃~70℃ and a 10⁻⁵Pa vacuum environment, the luminance retention rate shall be ≥95% and color shift ΔE ≤2, ensuring no black screen at low temperatures and no afterimage at high temperatures. Under radiation resistance (total dose ≥100 krad), there shall be no pixel failure to prevent loss of critical data.

● Adaptability to High-Light and Low-Light Environments: In the face of high-altitude strong light (≥100,000 lux), luminance must be ≥2000 cd/m² with reflectivity ≤1% to prevent glare. In nighttime or in-cabin low-light environments, luminance can be reduced to ≤1 cd/m² without afterglow residue, avoiding interference with night vision capability.

● Display Accuracy and Stability: The deviation of luminance/chromaticity uniformity shall be ≤3% to ensure no visual misleading in data charts. The response time shall be ≤20ms, with no motion blur in the dynamic display of real-time parameters (e.g., flight trajectory, cabin pressure) to guarantee operational synchronization.

● Reliability and Durability: After 10,000 power-on/off cycles and 10-2000Hz vibration tests, the optical parameter drift shall be ≤5% with no physical damage (such as glass breakage or film layer peeling), adapting to frequent takeoffs/landings or launch impacts.

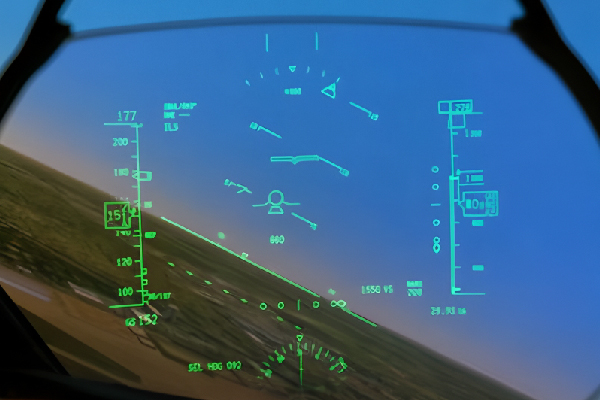

Airborne HUD Optical Testing System

Aerospace HUD projects critical flight parameters (such as altitude, speed, and flight path) onto the cockpit windshield or helmet-mounted display, ensuring pilots' line of sight does not deviate from the external environment. The key evaluation focuses include:

● Projection Accuracy: Virtual image distance (fixed at 5–10 meters to match high-altitude visual distance), distortion rate ≤0.5% to avoid misjudgment caused by data misalignment; luminance uniformity deviation of characters/graphics ≤5% with clear edges without blurring.

● Penetrability in Complex Light Environments: In scenarios such as direct sunlight, cloud reflection, and nighttime starlight, the virtual image contrast ratio ≥1000:1 to ensure data visibility; resistance to stray light interference (e.g., engine exhaust flame light) with no glare or light spot interference.

● Multi-Scenario Adaptability: For different flight phases (takeoff, cruise, landing), automatically switch luminance (500–3000 cd/m²) and display modes to adapt to changes in external light intensity; helmet-mounted HUDs must support a viewing angle range of ±30° horizontally and ±20° vertically, covering the pilot’s natural field of view.

● Safety and Compatibility: Projected light intensity does not interfere with the use of night vision goggles (NVG) (near-infrared band intensity ≤0.1 cd/m²); matches the optical characteristics of the windshield with no ghosting or reflection loss (light transmittance loss ≤3%).

Airborne Lighting Optical Measurement System

Aerospace lighting covers cockpit lighting, cabin lighting, and external identification lighting, etc., which must balance functionality, safety, and ergonomics. The evaluation dimensions are as follows:

● Cockpit Lighting: The adjustable luminance range of instrument panel lighting is 0.1-50 cd/m², with a color temperature of 3000K-5000K (to avoid blue light interfering with night vision) and no direct glare (glare level ≤1). The luminous intensity of buttons/indicator lights is uniform, and their colors comply with international standards (e.g., red for warning, green for normal) to ensure quick recognition.

● Aerospace Cabin Lighting: It features a gradual luminance range of 0.5-100 cd/m² and supports sunrise/sunset simulation (automatic switching of color temperature between 2700K-6500K) to reduce passenger jet lag discomfort. Emergency lighting maintains luminance ≥10 cd/m² for ≥90 minutes after power failure to guide evacuation routes.

● External Identification Lighting: Navigation lights (red, green, white) have luminous intensity complying with ICAO standards (≥1000 cd) and angular visibility ≥110° to ensure long-distance recognition. Anti-collision lights have a flicker frequency of 40-60 times/minute and strong penetration in fog and rain (visible distance ≥5km at 1km visibility).

● Extreme Environment Tolerance: Lighting components show no filament burnout or LED failure in environments of -60℃~80℃ and low pressure, with vibration resistance (20-2000Hz) and impact resistance (1000G acceleration) to ensure long-term stable operation.