A key point in the manufacturing process of flexible foldable OLED screens and materials is whether they can avoid severe creases and damage during folding within their designed service life. Calculated based on a user folding 100 times per day over 5 years of use, the product needs to withstand 200,000 folds. To ensure reliability throughout the service cycle, it is necessary to simulate the bending trajectory of finished products in a short time for dynamic bending verification of materials.

Based on the characteristics and bending requirements of flexible products, Fstar has independently developed a bending test platform that perfectly simulates motion trajectories through a 3-axis interpolation motion method. It can realize inward folding and outward folding tests under any bending radius without replacing tracks, meeting the bending testing needs of different products such as flexible screens, flexible steel sheets, and flexible OLED modules.

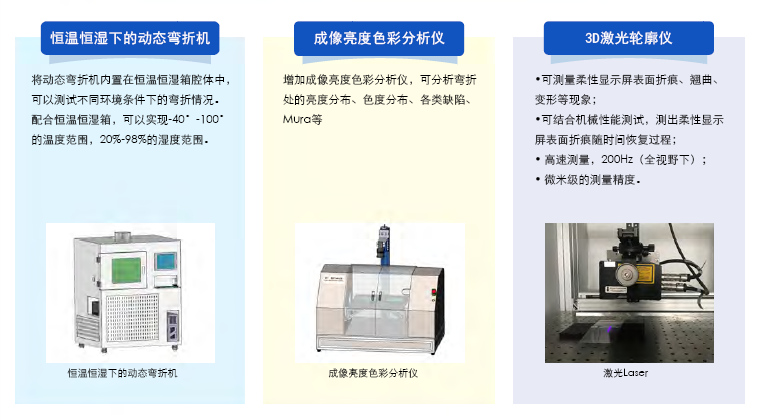

On the basis of realizing basic bending functions, the dynamic bending machine can also be equipped with other optional hardware to achieve more extensive functions.

{{data.abstract || "No product introduction available"}}